ENERGY & OCTG

INVEX software built for service centers focused on Energy and OCTG products.

The INVEX cloud-based metal software offers comprehensive functionality for metal and steel OCTG, bar and tube service centers or bar distributors. INVEX enables bar distributors to quickly take and ship orders with minimal screens and steps. Common business cases such as band sawing, turning, boring, or outside process such as trepanning can be handled quickly and out-of-the-box.

These OCTG, bar and tube companies, also referred to as OCTG bar and tube stockholders or distributors, normally carry a wide range of bar and tube products for the energy industry.

Orders can be fulfilled using the multi-step routing function that can fulfill an order across a single or multiple warehouses to saw or turn bar products.

This can include outside processing steps; all required transfers are automatically created.

CASES HANDLED:

- Fast entry of quotes and orders

- Receive inbound bars or tube while in-transit from the mill on a vessel, truck, or barge

- Fast entry of quotes and orders

- Fulfill pick and ship orders quickly

- Buyouts and back-to-back orders

- Direct ship orders (mill to customer direct)

- Ability to enter orders for repetitive customer parts

- Single or multi-step multi-plant processing

- Outside processing for heat treatment, trepanning or turning

- Handles common processes such as sawing, boring, and turning

- Counter sales

- Non-Conformance function for complaints and claims barge

Processes such as turning reduce the outside diameter (OD) of the bar. INVEX dynamically handles the new OD without the need to create a new product or part number for every possible diameter.

In cases such as turning and boring, the OD and ID are also dynamic in INVEX. INVEX dynamically handles the new OD/ID without the need to create a new product or part number for every possible diameter.

The item route handles multiple processing steps that can be performing across warehouses (plants) or to/from outside processors. All transfer requirements are created automatically.

SCALE YOUR BUSINESS

INVEX empowers Energy and OCTG processors to scale to different business requirements

- Products can be managed by tag, heat, or location control

- Pipe and tube are commonly inventoried by heat

- Specific or real-time average costing

- Flexible stock search by grade, finish, OD, ID, or wall

- Drop (remnants) can be viewed in the same inquiry as stock material

- Bar, pipe, and tube can maintain a fixed, mill, or random length designation

- Bars or tubes can be controlled by pieces, lineal measure, and weight

- Length can be maintained in feet and/or inches

- Stock screens shows pieces, footage/meters, and weight

- Receive bars at actual or theoretical weight

- Record Jominy test results

- Heat treatment test certificates can be attached to inventory

- Inventory Replenishment functions and tools

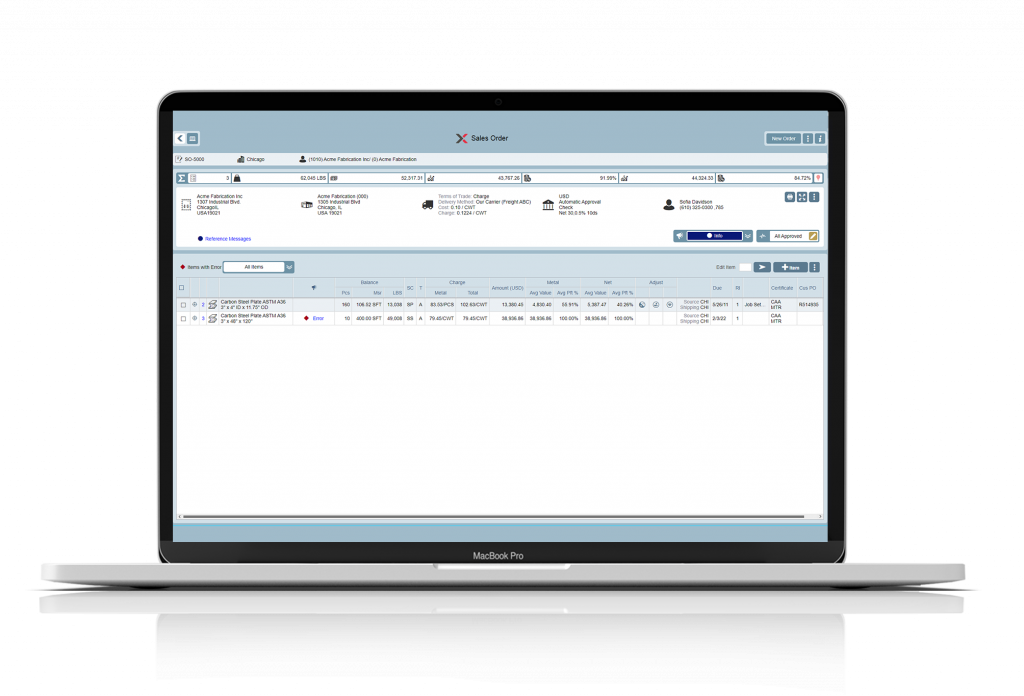

Fast entry of quotes and orders with real-time access to inventory and pricing information makes all the difference.

- Fast quote to order conversion

- Short cut entry mode to speed up quote entry

- Enter quotes for prospects

- Source a single order from different warehouses

- Enter a quote or order for bar to any diameter for turning process cases

- Enter a quote or order for tube to any OD/ID for turning & boring

- Integrated metal price book

- Sawing pricing tables

- Duplicate a quote or order

- Attach a diagram or file to a quote or order

- Multi-currency pricing

A highly advanced and integrated Sales Order Status Desktop enables sales and customer service staff to view a comprehensive status of a customer order. Consolidated in a single, clear view, the INVEX Sales Order Status includes production planning, scheduling, shop floor progression, outside processing status, ready-to-ship designation, and logistics status

- Value-add costing

- Capacity Planning

- Production Scheduling

- Multi-step processing (plasma burn, drill, grind)

- Item route can be across multiple warehouses (multi-plant)

- Item route can include outside processing steps

- Planning function to group multiple orders onto the same Production Job

- Drop (remnant) costing table to automatically reduce the cost of a drop

- Integration with plate nesting software SigmaNEST

- Record the run, setup, and down time

- Record picking on a mobile device

Picks can be recorded directly on the shop floor with a mobile device. The picker can scan the material being picked, print a shipping label, and if required package the material in a box directly from the mobile device. A label can be printed for the remaining bundle of material.

INVEX shipment planning is completely online. A comprehensive multi-layer inquiry to view sales orders and inter-warehouse transfers can organize and summarize orders by delivery route or shipping zone for better load consolidation.

- Transport lineup shows all planned delivery loads by scheduled date and time

- Shipping staff can view available capacity and route information

- Loading List can be printed to help load the truck

- Print a Packing List or Bill of Lading

- Sequence the stops

- Copy of the original mill cert or company certs are auto-printed and/or emailed

- Plan a load with multiple warehouse pick-up points

- Finished goods can be staged or live-loaded onto the truck

This function verifies that the material that is being loaded or has been loaded on a Vehicle is the correct material and that the transport includes all the items that were planned for delivery. Using a mobile device, the operator scans the barcoded Shipping Labels attached to the material that has been loaded.