PLATE

INVEX software built for service centers focused on plate processing

The INVEX cloud-based metal software offers comprehensive functionality for metal and steel plate service centers as well as plate processors. INVEX enables these metal companies to place an order for a variety of cut shapes or irregular sketches, and fulfill the order using a multi-step production functions. Common plate cutting business cases such as plasma cutting or oxy cutting can be handled quickly and out-of-the-box.

These metal companies, also referred to as metal and steel plate stockholders, normally carry a wide range of products which includes metal and steel plate of a variety of thicknesses and sizes.

Orders can be fulfilled using the multi-step routing function that can fulfill an order across a single or multiple warehouses.

This can include outside processing steps; all required transfers are automatically created.

CASES HANDLED:

VIEWING PLATE DIAGRAM

The processing of plate could yield a drop (also referred to as a remnant) plate with multiple cut outs or ‘dog legs’. This plate diagram can be recorded in INVEX and viewed in the stock inquiry.

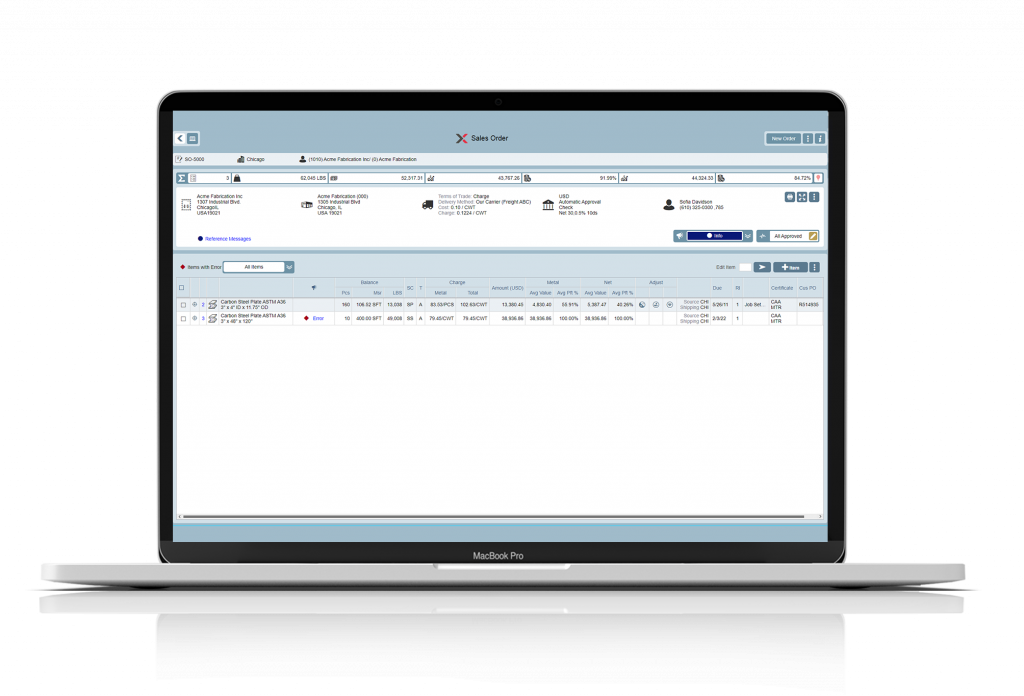

Fast entry of quotes and orders with real-time access to inventory and pricing information makes all the difference.

FEATURES:

ORDER STATUS:

A highly advanced and integrated Sales Order Status Desktop enables sales and customer service staff to view a comprehensive status of a customer order. Consolidated in a single, clear view, the INVEX Sales Order Status includes production planning, scheduling, shop floor progression, outside processing status, ready-to-ship designation, and logistics status

FEATURES:

PICKING

Picks can be recorded directly on the shop floor with a mobile device. The picker can scan the bar coded material being picked, print a shipping label, and if required package the material in a box directly from the mobile device. A label can be printed for the remaining bundle of material.

INVEX shipment planning is completely online. A comprehensive multi-layer inquiry to view sales orders and inter-warehouse transfers can organize and summarize orders by delivery route or shipping zone for better load consolidation.

FEATURES:

LOAD VERIFICATION

This function verifies that the material that is being loaded or has been loaded on a Vehicle is the correct material and that the transport includes all the items that were planned for delivery. Using a mobile device, the operator scans the barcoded Shipping Labels attached to the material that has been loaded.